There are several reasons to analyze coatings on metallic materials, it can be water- or vapor-side coatings on inside and outside tubes or vessels. The chemical analysis can give us answers on how efficient the plant is in operation and can be a measure of how quality or environmentally safe a process is.

Photo: Paul Praszkier, from Safe Control Boiler Service AB, performs an inspection of boiler tubes.

“In many industries, including Pulp & Paper and Energy, it is very important to regularly inspect and analyze the coatings on the boiler tubes, to plan for downtime and to prevent unwanted downtime and breakdowns,” says Catarina Wernlund, head of the Chemistry department at Safe Control Materialteknik AB.

A coating can vary greatly in thickness and appearance and consists of, for example, particles, flakes and fibers. An assignment can be to investigate how a coating/discoloration/dust or, as we can say in everyday speech, “dirt” has arisen and where it originates from. We can analyze coatings on many different details and materials, such as packaging, circuit boards and filters.

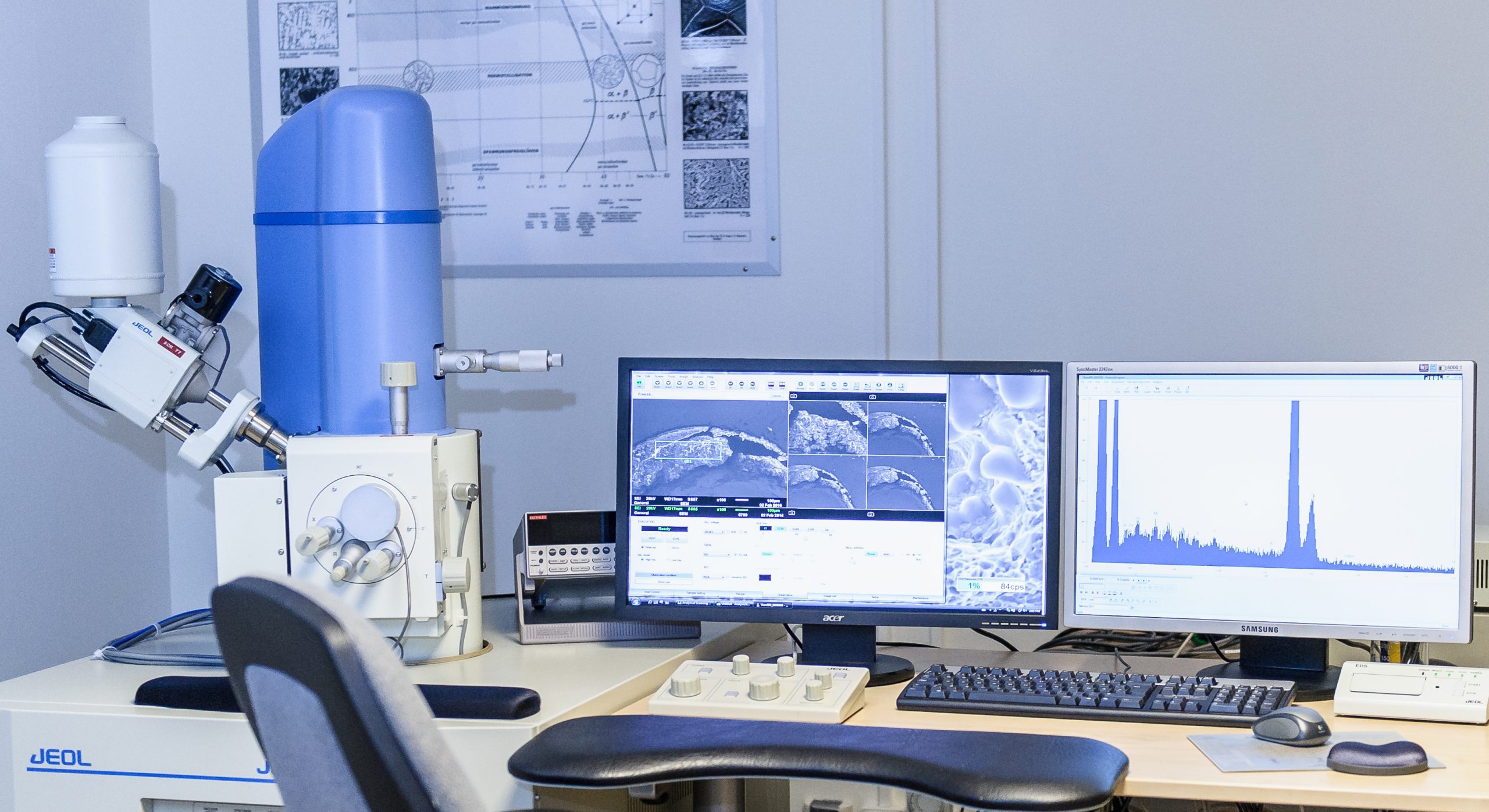

Chemical analysis in Scanning Electron Microscope

We perform analyzes on desired and unwanted coatings with general analyzes where the constituent chemical substances are mapped. We also perform wet chemical analyzes, where the coatings dissolves in, for example, acid, and each substance is carefully analyzed.

When analyzing coatings from, for example, corrosion point of view, a scanning electron microscope (SEM) is an important aid. Constituent elements can be qualitatively analyzed and with so-called mapping, the distribution of specific elements can be documented. Our SEM is equipped with an energy-dispersive X-ray spectrometer (EDS/EDX), which provides the opportunity to chemically analyze the composition, both qualitatively and quantitatively, on the surface of the areas being examined, so called spot check.

In the laboratory, we also have the opportunity to perform various combustions, weight determinations and other physical analyzes of coatings. An example is ash content and DWD (Deposit Weight Density). Soda melts and ashes are analyzed wet chemically according to the specified standard.

Want to know more about how we can help you with analysis of coatings?

Contact Catarina Wernlund on telephone +46 (0)31-65 64 93.

Safe Control Materialteknik AB

A business with a long history

Due to the company’s twentieth anniversary this year, we look back at history.

Our business dates back to Götaverken’s material laboratory in the 1910s. In 1991, the laboratory was sold to FFV Materialteknik.

After some constellations, Safe Control Materialteknik was formed in 2001 with the current owners.

Moments in time

in 1970, Götaverken was divided into three profit centers. One of them, Steam Technology, manufactured steam, bark and recovery boilers for the cellulose industry, where Paul Praszkier worked. In 1991, the business was sold to Norwegian Kvaerner.

In 2002, Paul started Safe Control Boiler Service, which focuses on inspection of recovery boilers with associated analyzes of coatings.

Did you know that Götaverken was once the world’s largest shipyard?

The yard’s and Safe Control’s history can be read on our website »

Requested seminar in digital format

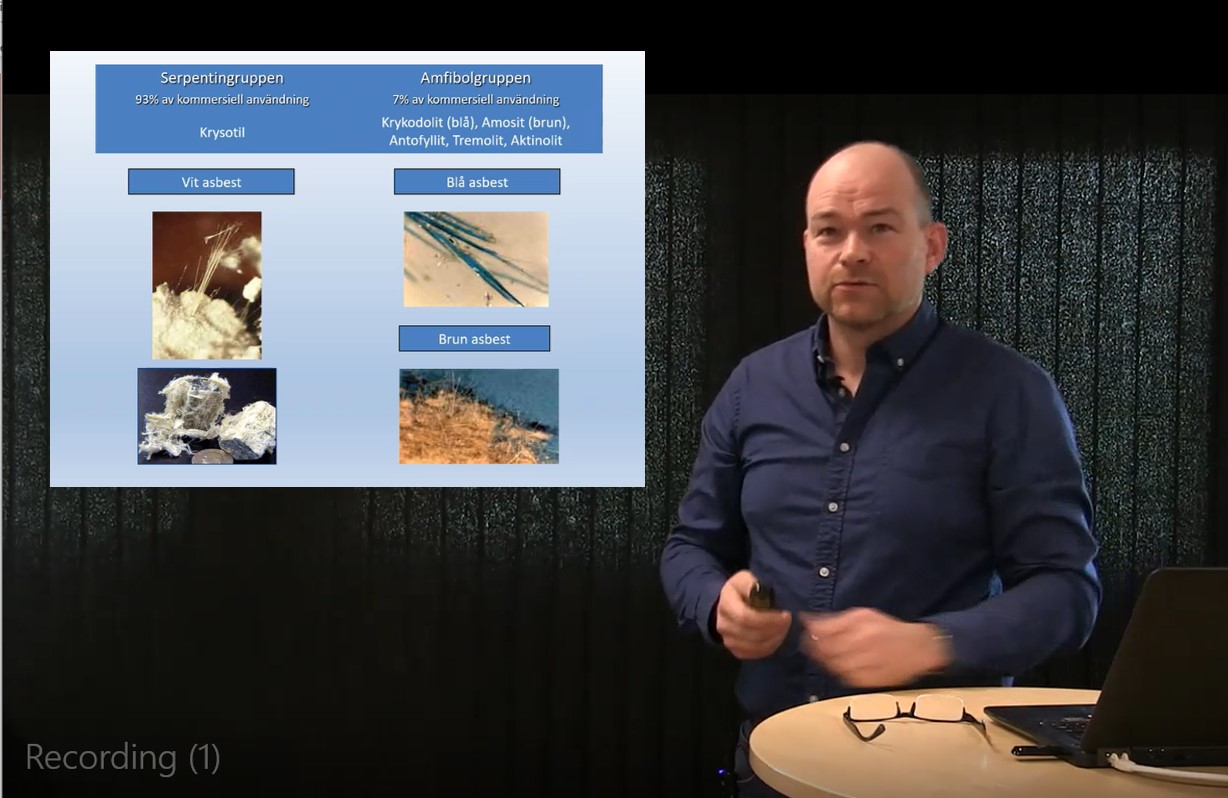

On May 27, it was finally time for a new breakfast seminar on asbestos, something that has been in high demand. This time as a webinar.

Our lecturer, Jonas Mogvall, began with a historical overview. Even in Roman times, people were aware of the good properties of asbestos and probably even though it was dangerous to health, many slaves died after breaking asbestos.

Although our knowledge today is much greater about the health risks, it is estimated that just over 100 people (some sources mention 1,000 people) die every year in Sweden, as a result of asbestos exposure.

We are planning for more breakfast seminars this autumn and depending on the authorities’ recommendations, they will be physical or digital..

Asbestos analysis and where asbestos can occur »

Time to book this autumn’s asbestos educations

Our asbestos educations will return in September and you can sign up now. The educations is carried out according to the authorities’ recommendations and we hope to be able to have them with physical participation in our facilities.

- Asbestos for work management (full day)

September 2, 2021 - Asbestos, basic (half day)

September 3, 2021

Our complete education program »

A warm welcome to celebrate 20 years with Safe Control!

We already want to tell you that we are planning for an event this autumn. Keep an eye out for our invitation that comes via email in August.